Order Acceptance & Instruction Issuance

无论客户订单大小,我们都采用高水平的技术,根据客户提供的设计规格和数据,通过试生产运行,在尽可能短的时间内取得成果。如果客户没有设计规范,我们可以使用CAD从雏形图纸中创建它们。我们拥有完整的生产系统,可以通过材料选择,材料组合,金属模具制作,测试生产和批量生产来适应个性化客户的需求。测量数据等也可根据客户的要求提供。

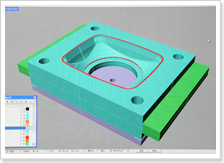

Metal Mold Creation & Metal/Resin Processing

| Closer contact with clients through 3DCAD-CAM | Peculiar knowhow has been made the best

use of for manufacturing the metal mold. |

| |

| On site equipment for manufacturingrubber molds enables us to better meet client needs |

| | NC electric discharge machine |

|

| |

| Scenery under Processing. |

|

|

|

Material Blending

We support more than 1,000 differentmaterial combinations. Naturally, we also support original combinations

Adhesive Coating Application

Coating of adhesive for vulcanization(for a variety of rubber and metal combinations)

Cutting

The raw material is cut according tothe metal mold.

Molding

A highly accurate product that cannot correspond with an automatic machine is produced in a technology superior of the skilled worker.

Automatic vulcanization

molding machine

| Vulcanization molding machine

for making for trial purposes

|

Finishing

Bali is removed freezing rubber with the chokedamp

| Bali is processed by a skilled technology |

|

|

Grinding & Cutting

We offer grind processing for high-precision andcomplicated shapes, such as components with an external diameter common differenceof 15 microns.

Inspection

Strict quality control that used inspection process standard and OK boundary sample.

Components are inspected for flowslike needlepoints.

Non-contact rubber testing

Packaging & Shipping

Component specifications are provided upon request.