Processes

Processes

Production Technology

Order Acceptance & Instruction Issuance

Regardless of the production quantity, we employ a high level

of technology to achieve results in the shortest time possible through test production

runs based on design specifications and data provided by the client. If design

specifications are unavailable, we can create them from sample drawings using

CAD. We are proud of our complete production system, which can be adapted to

suit individual client needs through material selection, material combinations,

metallic mold creation, test production and production volume. Measurement data,

etc. can also be provided upon request.

of technology to achieve results in the shortest time possible through test production

runs based on design specifications and data provided by the client. If design

specifications are unavailable, we can create them from sample drawings using

CAD. We are proud of our complete production system, which can be adapted to

suit individual client needs through material selection, material combinations,

metallic mold creation, test production and production volume. Measurement data,

etc. can also be provided upon request.

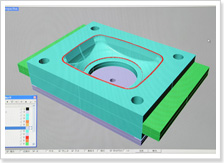

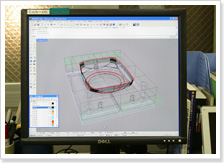

Metal Mold Creation & Metal/Resin Processing

| Closer contact with clients through 3DCAD-CAM | Peculiar knowhow has been made the best use of for manufacturing the metal mold. | ||||||

|

| ||||||

| On site equipment for manufacturingrubber molds enables us to better meet client needs | |||||||

|

| ||||||

|

| ||||||

| |||||||

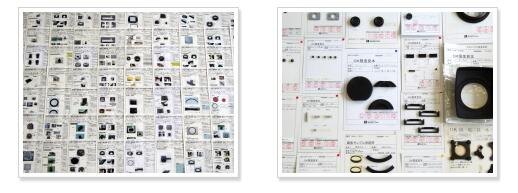

Material Blending

We support more than 1,000 differentmaterial combinations. Naturally, we also support original combinations

Adhesive Coating Application

Coating of adhesive for vulcanization(for a variety of rubber and metal combinations)

Molding

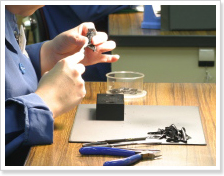

A highly accurate product that cannot correspond with an automatic machine is produced in a technology superior of the skilled worker.

| Automatic vulcanization molding machine | Vulcanization molding machine for making for trial purposes |

Finishing

| Bali is removed freezing rubber with the chokedamp | Bali is processed by a skilled technology |

|  |

Grinding & Cutting

We offer grind processing for high-precision andcomplicated shapes, such as components with an external diameter common differenceof 15 microns.

|  |

Copyright © 2014-2024 Luen Shun Rubber Products Co., Ltd.